Over the last ten years, Dubai’s manufacturing scene has seen significant change. By providing beam-laser cutting services, the emirate has emerged as a regional center for precision manufacturing. A project’s success or expensive delays can be determined by knowing the benefits of choosing the best beam laser cutting service price Dubai affordably.

Accuracy Compliant with International Standards

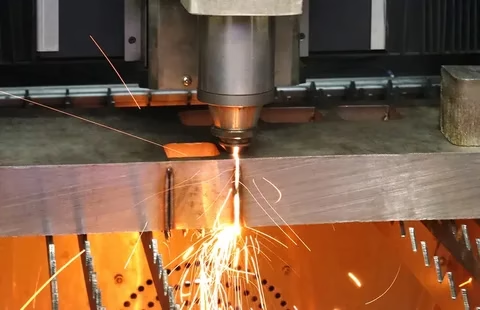

Dubai’s beam-laser cutting services provide accuracy comparable to that of the top manufacturing hubs worldwide. In order to cut through materials with few heat-affected zones, the technology underlying these services uses concentrated light beams. By comparison with conventional cutting techniques, this results in smoother edge finishes and less distortion of the material. Businesses that require parts that fit together precisely will find this accuracy helpful.

Fiber lasers, CO2 lasers, and specialized systems for certain materials are among the several laser types frequently used in Dubai’s beam laser cutting facilities. This range makes sure that the best technology is used for every project, maximizing quality and laser cutting service cost in Dubai.

Expanded Opportunities Due to Material Versatility

The materials that beam-laser cutting services are capable of handling are constantly growing. Dubai’s broad industrial base benefits from this adaptability. Steel components must be cut precisely for construction enterprises. Manufacturers of electronics need thin materials to be sliced precisely. Multiple material types are required by automotive suppliers. These needs can frequently be met by a single-beam laser cutting service provider.

Capabilities for thickness have also become amazing. Modern systems are able to cut steel plates up to 40 mm thick, while tiny materials as thin as 0.1 mm can be treated easily. Without the need for several suppliers or procedures, this range covers the majority of industrial applications.

Advantages of Speed: Establish Project Timelines

Timelines for production are frequently hampered by traditional cutting techniques. Many of these delays can be avoided using beam-laser cutting services. There are no physical tools required, so setup times are quite short. Cutting nearly instantly starts, and programs load rapidly.

The precise cutting speeds vary depending on the kind of material and its thickness, although laser systems usually beat mechanical, waterjet, or plasma cutting by a considerable amount. Complex forms that would take several passes on traditional equipment are finished in a single pass.

The industrial climate in Dubai is competitive, which encourages quick turnaround times. Businesses that are able to provide completed goods rapidly benefit greatly. Beam-laser cutting services are directly responsible for these shorter lead times.

Economical Utilization of Various Channels

End customers benefit from a number of cost advantages shown in the beam laser cutting service pricing that Dubai’s market offers. With its small kerf widths and accurate nesting algorithms, laser cutting maximizes material use.

Because less operator assistance is needed when using laser cutting, labor expenses go down. The systems operate mainly without human intervention after programs are loaded and items are placed. Hourly prices remain competitive due to this automation, which also maintains constant quality.

The physical contact between cutting tools and materials during traditional cutting results in wear and replacement expenses. This wear is removed by laser cutting, maintaining steady and predictable operating expenses.

There are often extra savings when ancillary operations are eliminated. Frequently, parts are delivered from laser cutting tables with little to no finishing needed or ready for assembly. By doing this, extra handling, shipping, and processing procedures are removed.

Consistency in Quality Develops Reliability

A key component of successful manufacturing is repeatability. The results of beam-laser cutting services are the same for hundreds or thousands of items. Documentation proving that every part satisfies standards is necessary for the automotive, medical, and aerospace industries. Traceability and compliance are ensured by the comprehensive cutting parameter logs that laser cutting systems provide.

Additionally, quality consistency lowers inspection expenses and time. As systems demonstrate dependability, the need for incoming inspections frequently declines. Supply chains are streamlined, and project expenses are decreased overall.

Flexibility in the Evolution of Design

Rarely does product development go in a straight line. Flexibility in manufacturing is necessary for engineering advancements, customer requirements, and design modifications. These adjustments are accommodated by beam-laser cutting services without requiring significant retooling.

Dubai, being a regional Biz hub, has several businesses that are appealing to the diverse markets with various needs. Rapid changeovers of different part numbers or specifications have a high competitive benefit.

The Natural World Matters

Compared to traditional methods, modern beam-laser cutting services present fewer effects on the environment. Laser precision means wastage is kept to a minimum, and some systems effectively collect and clean discharges. Increased energy efficiency has been achieved by advances in the field of lasers.

Due to a focus on development in a sustainable manner, manufacturing operations are paying more attention to environmental performance. Sustainability Green: The environmental benefits of laser cutting services can align with broader corporate sustainability goals of those businesses that use them.

Strategic Location Advantages

Because of its strategic location, Dubai offers logistical benefits that raise the cost of beam-laser cutting services. An entry point to markets in Africa, Asia, and Europe is the emirate. Effective material sourcing and completed goods distribution are made possible by this site.

Additionally, synergies are produced by the concentration of manufacturing services in Dubai. Businesses can frequently acquire several services from local institutions, which lowers the complexity of coordination and transportation costs. This cluster effect maintains the low cost of Dubai’s beam laser cutting services while maintaining service quality.

Technology Investment Fuels Progress

The ongoing technological investments in Dubai’s beam-laser cutting services are beneficial. The most recent automation, software, and laser systems are adopted due to competition among service providers. Better capabilities and more affordable prices for clients are the results of these initiatives.

The city draws technology suppliers and expertise because of its aim to become a hub for smart manufacturing. Beam laser cutting services are kept up to date with growing capabilities and worldwide best practices thanks to this environment.

Conclusion

Selecting beam laser cutting services in Dubai at competitive costs offers firms cost advantages, speed, flexibility, and precision that promote business expansion. A strategic location, knowledgeable operators, and cutting-edge technology combine to produce value propositions that go far beyond straightforward financial concerns.