In the ever-evolving textile industry, 2025 marks a turning point for sustainability—especially in the world of recycled yarn manufacturing. As global environmental concerns intensify and fashion brands demand greener materials, Recycled Yarn Manufacturers are stepping up with breakthrough innovations that redefine quality, process, and environmental impact.

This article explores the latest developments in recycled yarn, highlighting the technologies, practices, and global shifts that are setting new benchmarks in sustainable textile production. Whether you are a textile buyer, fashion brand, or eco-conscious entrepreneur, understanding these advancements can help you make informed decisions while contributing to a greener future.

🌱 Why Recycled Yarn Matters More Than Ever

The textile industry has long been under scrutiny for its environmental footprint—ranging from water overuse to massive waste generation. Recycled yarn, made from post-consumer waste like PET bottles, used garments, or post-industrial textile scraps, offers a viable solution. It reduces landfill waste, saves energy, and drastically cuts water consumption.

With brands globally pledging net-zero goals and circular supply chains, recycled yarn suppliers are now central to the conversation around eco-conscious manufacturing.

🔧 Top Innovations in Recycled Yarn Manufacturing – 2025 Highlights

1. AI-Powered Fiber Sorting Systems

Traditional recycling methods often struggle with separating fiber types, especially blended fabrics. But in 2025, AI-powered sorting systems are revolutionizing fiber identification. These systems use machine learning algorithms and hyperspectral imaging to:

- Detect fiber composition (cotton, polyester, viscose)

- Separate blends accurately

- Enhance raw material quality before spinning

By improving fiber segregation, recycled yarn manufacturers are now producing yarns with more consistency and strength, even from mixed-fiber waste.

2. Low-Impact Dyeing Technologies

Dyeing remains one of the most pollutive stages in textile production. The latest low-impact dyeing techniques allow recycled fiber yarn to be colored without traditional chemical-heavy methods.

Some 2025 breakthroughs include:

- Supercritical CO₂ dyeing (waterless and chemical-free)

- Dope dyeing (adding pigments during fiber formation)

- Natural dye integration into recycled yarn lines

These innovations save thousands of liters of water per kilogram of yarn while producing long-lasting, vibrant colors.

3. Closed-Loop Recycling Systems

Manufacturers are adopting closed-loop systems, where waste from spinning and weaving is reprocessed within the same facility. This not only minimizes production waste but also creates a continuous recycling chain, resulting in:

- Reduced material loss

- Lower energy consumption

- Greater traceability and transparency

Brands working with a recycled yarn supplier that uses closed-loop systems often see this as a value addition to their sustainability claims.

4. Blockchain for Traceability

In 2025, traceability isn’t a luxury—it’s a necessity. Yarn manufacturers are integrating blockchain technology to ensure every stage of the recycled yarn lifecycle is transparent and verifiable.

Blockchain systems allow buyers to:

- Track yarn from waste collection to spinning

- Verify certifications and origin

- Monitor carbon footprint across the supply chain

This tech integration enhances trust and appeals to eco-conscious brands and consumers alike.

5. Advanced Mechanical and Chemical Recycling Fusion

Earlier, manufacturers relied solely on mechanical recycling (shredding old textiles into fibers), which degraded quality over time. In 2025, hybrid recycling—a fusion of mechanical and advanced chemical processes—has emerged.

This approach allows:

- Extraction of pure cellulose or polyester from blended fabrics

- Restoration of fiber quality to nearly virgin standards

- Expansion into recycling complex materials like spandex blends

This means recycled yarn is no longer a compromise on quality—it’s now a high-performance, sustainable alternative.

🧵 How These Innovations Are Shaping the Industry

The recycled yarn industry is no longer a niche. Thanks to technological advances, recycled yarn manufacturers are now supplying to diverse sectors:

- Fashion and Apparel: Premium recycled cotton and polyester yarns for both fast fashion and luxury.

- Home Furnishings: Durable yarns used in upholstery, curtains, and rugs.

- Automotive: High-tenacity recycled yarns for seat covers and insulation.

- Technical Textiles: Specialized applications in filtration, construction, and packaging.

As a result, the market demand for certified and innovative recycled yarn suppliers is booming.

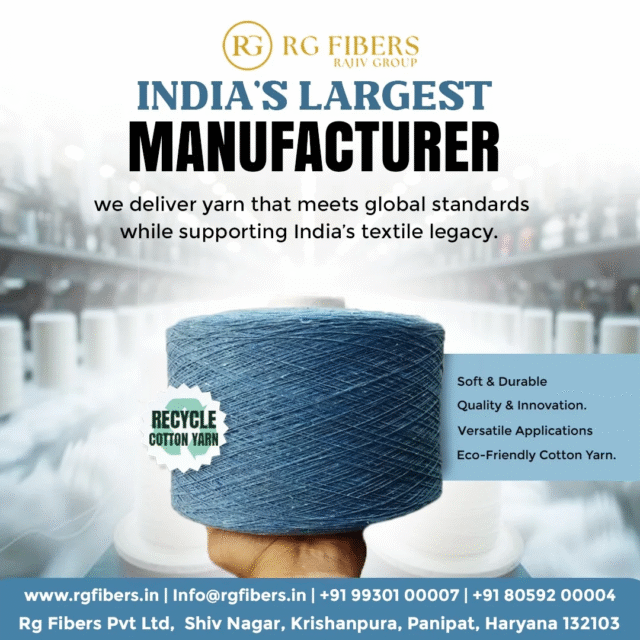

🏭 Spotlight: Rajiv Group’s Sustainable Transformation

One of the leading names in India’s textile space, Rajiv Group, has been at the forefront of innovation in the recycled yarn sector. As a reputed yarn manufacturer, they have invested heavily in smart recycling machinery, low-emission spinning processes, and waste traceability systems.

Their offerings include:

- High-quality recycled cotton yarn for knitting and weaving

- Recycled fiber yarn blends optimized for color fastness and strength

- Custom dye-to-match capabilities using eco-friendly pigments

By combining quality and sustainability, Rajiv Group is bridging the gap between performance and environmental responsibility.

📈 What to Look for in a Recycled Yarn Supplier in 2025

If you’re sourcing recycled yarn for your production needs, ensure your supplier is keeping up with 2025’s innovations. Here are key indicators:

✅ Certifications: GRS (Global Recycled Standard), OEKO-TEX, ISO

✅ Technological Adoption: Use of AI, blockchain, and closed-loop systems

✅ Environmental Reporting: Transparent data on water savings and carbon reduction

✅ Customization & R&D: Willingness to innovate for your fabric or color needs

✅ Global Logistics: On-time delivery and export capabilities

Choosing the right recycled yarn manufacturer isn’t just about price—it’s about long-term partnership and shared values.

🌟 The Road Ahead

Innovation in recycled yarn manufacturing is rewriting the rules of sustainability in textiles. With growing awareness, technological evolution, and regulatory push, the shift towards eco-friendly materials is no longer optional—it’s inevitable.

For brands, suppliers, and manufacturers, embracing these 2025 innovations means not just staying relevant, but leading the change toward a circular economy.

So whether you’re a startup looking for recycled fiber yarn or a global apparel brand in search of a trusted recycled yarn supplier, now is the time to invest in innovation—and in our planet.

Ready to explore sustainable yarn solutions? Partner with forward-thinking manufacturers like Rajiv Group and be a part of the eco-revolution in textiles.