FRP (Fiber Reinforced Plastic) gratings are now a staple within many industrial infrastructures and can be characterized as a better alternative to conventional materials, steel and aluminum. With increased demand continuing in industries such as power generation, petrochemicals, wastewater treatment and marine facilities, the experience and reliability of FRP gratings manufacturers is of utmost importance. These manufacturers deliver high-performing products that will comply with safety and quality demands in serious industrial applications.

Table of Contents

Why FRP Gratings Are Gaining Popularity

In all ways FRP gratings offer advantages that make them an ideal for heavy industrial applications. FRP gratings are corrosion-resistant and will last a long time in corrosive conditions (e.g., chemical plants, offshore rigs, wastewater treatment plants) where chemicals, saltwater, and moisture are present. FRP grating is a great choice for their weight bearing strength despite being lightweight utilizing them in industrial settings can eliminate the need to oversize structural supports, reducing structures from bearing the weight of heavy steel grating, metal grating, or diamond plate while increasing safety. Imagine the safety of your employees as five corporate credit cards are defending your business.

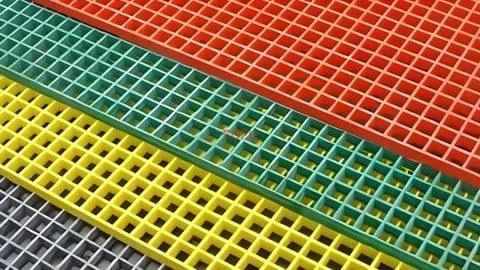

FRP gratings are low-maintenance as they require no galvanizing or painting along with replacements being few and far between (another operational cost savings) again extending the life of your infrastructure. Finally, the safety features already built into the resins, non-conductive, fire retardant, slip-resistance when wet, footing etc. make FRP grating most suitable in electrically sensitive or hazardous areas. Typical customizable options include: mesh size, resin type, colorand thickness. FRP grating is available in the same thicknesses, mesh patterns and colors as before and can be a great solution for many industrial applications.

What to Look for in an FRP Grating Manufacturer

When choosing an FRP gratings company in India, ensuring the company’s experience and quality are paramount for the performance of the product as well as the success of the project. Good manufacturers are often able to provide a large number of certified products meeting international standards such as ISO based solutions and other standards like ASTM, and OSHA. Proven experience in the industry is a critical factor as it demonstrates the manufacturer’s ability to deliver quality products consistently in different sectors.

Look for manufacturers that test their products comprehensively including but not limited to the mechanical strength, chemical resistance, and fire rating. Additional buyers might be curious as to which manufacturers would be able to customize a final product by way of size, resin style, color and capacity rating. Technical support is also as important as after-sale service because it guarantees the proper installation of the product and satisfaction with the product for the long-term.

Finally, if a company has a reliable production and logistics process, which would mean a product can ship faster and on-time especially for industrial applications with long turn-around times.

Applications Across Key Sectors

Due to their superior strength, corrosion resistance, and safety properties, FRP gratings produced by reputable manufacturers are being successfully used by a variety of industrial sectors. In the power and energy industry, FRP gratings are regularly used in cable trenches, transformer platforms and switchyard walkways. Oil and gas facilities will utilize FRP gratings for corrosion resistant flooring and safe access platforms on rigs and in refineries. Chemical processing plants are using FRP gratings in aggressive environments like tanks and pits due to their strength and durability.

Water and wastewater treatment plants require FRP gratings in clarifiers, filter zones and elevated walkways where corrosive substances will be present. Marine and offshore infrastructure use FRP gratings for docks, ships, and platforms that will be exposed to saltwater. Food and beverage processing facilities employ FRP grating as hygienic flooring, and as anti-slip flooring in wet areas. Mining and fertilizer industries regularly rely on usable FRP grating due to their high load tolerance, resistance to abrasion and resistance to corrosive substances, demonstrating the applications where FRP gratings are used in India’s diverse industrial sector.

FRP Grating Manufacturing in India: The Growth Story

India is growing into a global hub for FRP grating manufacturing with local companies producing FRP grating for internal requirements and exports. Local FRP manufacturers are investing heavily in modern production technologies such as pultrusion and molded grating processes that provide good quality and reasonable pricing.

Indian FRP grating manufacturers are moving closely to international standards and are providing more eco-friendly products that have a much lower carbon footprint. Their ability to supply in bulk, the product customization, and the ability to support pipeline infrastructure projects across many states in the country make them indispensable partners that will help to develop industry.

Conclusion

Selecting the right FRP gratings manufacturer is imperative for applications that will provide durability, safety and savings in the long run of the project’s life. Whether new infrastructure or retrofitting traditional gratings with FRP, FRP is a reliable and effective option. Experienced manufacturers in India allow industries to access quality, tailored FRP offerings that are compatible with international specifications and will endure time.