You’re holding a sleek smartphone, sitting on a cushioned chair, or driving a car with a shiny dashboard. Ever wonder what ties these everyday items together? Polymers and resins, the unsung heroes of modern manufacturing, are quietly reshaping how we make things. These versatile materials are like the Swiss Army knives of industry—flexible, strong, and endlessly adaptable. From lightweight plastics to tough coatings, they’re driving innovation while keeping costs down. In Pakistan, where manufacturing fuels economic growth, these materials are game-changers. This blog dives into how polymers and resins are transforming industries, their unique properties, and why they’re indispensable. Whether you’re a manufacturer or curious about the materials in your life, let’s uncover how polymers and resins are molding the future, with insights on sourcing from a chemical supplier in Pakistan!

What Are Polymers and Resins?

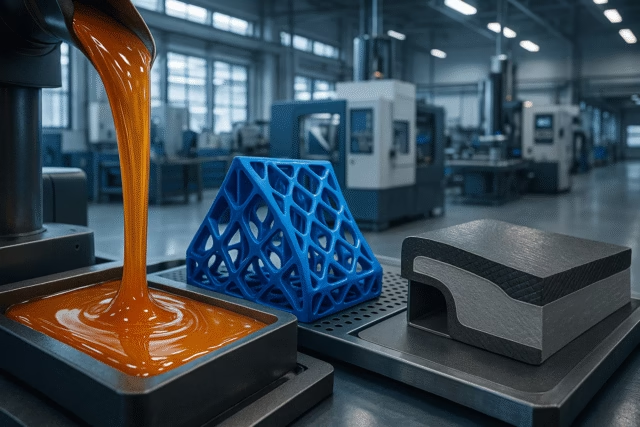

Polymers are large molecules made of repeating monomer units, while resins are a subset, often viscous, used for coatings or adhesives. Both are critical in manufacturing.

- Polymer Basics – Formed by linking monomers like ethylene, polymers create materials like plastics, fibers, or rubber for diverse applications.

- Resin Specifics – Resins, like epoxy or polyester, are polymers with sticky, hardening properties, ideal for bonding or protective layers.

- Natural vs. Synthetic – Natural polymers include cellulose in plants; synthetic ones, like nylon, are engineered for industrial needs.

- Production Process – Polymerization reactions, often petroleum-based, create these materials, supplied by resin suppliers for manufacturing.

- Pakistan’s Role – Local industries rely on these materials for textiles, packaging, and construction, driving demand for chemical suppliers.

What Types of Polymers and Resins Are Used in Manufacturing?

Polymers and resins come in various forms, each tailored for specific industrial roles.

- Thermoplastics – Polyethylene and PVC, which soften when heated, are used for pipes, bottles, and packaging due to their recyclability.

- Thermosets – Epoxy and phenolic resins harden permanently, perfect for durable coatings, adhesives, or electrical insulation.

- Elastomers – Rubber-like silicone or polyurethane stretch and rebound, ideal for tires, seals, or flexible medical tubing.

- Fiber Polymers – Polyester and nylon form strong threads for textiles, ropes, or carpets, valued for their tensile strength.

- Bio-Based Polymers – Polylactic acid (PLA) from corn offers eco-friendly options for packaging or disposable goods.

Polymers and resins are the backbone of modern manufacturing, bending and bonding to meet any challenge.

How Do Polymers Transform Manufacturing Processes?

Polymers streamline production, offering flexibility and efficiency across industries.

- Lightweight Materials – Polymers like polypropylene reduce product weight, cutting transport costs in automotive and aerospace manufacturing.

- Cost Savings – Affordable production of plastics and fibers lowers expenses, making goods like packaging or clothing accessible.

- Customizable Designs – Polymers can be molded into intricate shapes, enabling complex parts like phone casings or medical devices.

- Rapid Prototyping – Thermoplastics allow quick molding for testing designs, speeding up innovation in product development.

- Scalability – Polymer suppliers in Pakistan provide bulk materials, supporting large-scale production for local and export markets.

What Role Do Resins Play in Manufacturing?

Resins, a specialized polymer category, enhance durability and functionality in products.

- Protective Coatings – Epoxy resins shield surfaces in cars, buildings, or electronics, resisting corrosion and wear for long-lasting protection.

- Adhesive Strength – Resins bond materials in construction or aerospace, creating strong, reliable joints for structural integrity.

- Composite Materials – Resins combine with fibers to form lightweight, strong composites for boat hulls or wind turbine blades.

- Electrical Insulation – Phenolic resins protect circuits in electronics, ensuring safety and performance in high-voltage environments.

- Aesthetic Finishes – Resins add glossy or matte finishes to furniture or automotive parts, enhancing visual appeal and durability.

Comparing Polymers and Resins in Manufacturing

| Material | Primary Use | Key Features | Industry Applications |

| Thermoplastics | Packaging, pipes | Flexible, recyclable, lightweight | Bottles, films, plumbing |

| Thermoset Resins | Coatings, adhesives | Permanent set, durable, heat-resistant | Construction, electronics |

| Elastomers | Tires, seals | Stretchy, resilient, flexible | Automotive, medical devices |

| Fiber Polymers | Textiles | Strong, durable, thread-like | Clothing, carpets, ropes |

| Bio-Based Polymers | Eco-friendly packaging | Biodegradable, renewable | Disposable goods, containers |

How Are Polymers and Resins Used in Pakistan’s Industries?

Pakistan’s manufacturing sector leverages polymers and resins to drive growth and innovation.

- Textile Industry – Polyester fibers, a polymer staple, fuel Pakistan’s clothing exports, creating durable fabrics for global markets.

- Packaging Sector – Polyethylene and PET polymers dominate food and beverage containers, ensuring safety and affordability for consumers.

- Construction Growth – Epoxy resins and PVC strengthen buildings, pipes, and infrastructure, supporting Pakistan’s urban expansion.

- Automotive Manufacturing – Polymers reduce vehicle weight, while resins coat parts, improving efficiency and aesthetics for local production.

- Electronics Boom – Resins insulate circuits and polymers form casings, supporting Pakistan’s growing tech manufacturing capabilities.

Are Polymers and Resins Environmentally Friendly?

The environmental impact of polymers and resins is a critical concern, with both challenges and solutions emerging.

Environmental Challenges

- Plastic Waste – Non-biodegradable polymers like polyethylene contribute to pollution if not recycled, a challenge in Pakistan’s waste systems.

- Energy Use – Producing synthetic polymers and resins is energy-intensive, often relying on fossil fuels, increasing carbon emissions.

- Chemical Runoff – Resin production can release pollutants if not managed, impacting water sources and ecosystems.

Sustainable Solutions

- Recycling Programs – Recycling thermoplastics and some resins reduces waste, with Pakistan investing in better recycling infrastructure.

- Bio-Based Alternatives – Polymers like PLA, made from renewable sources, offer biodegradable options for packaging and disposables.

- Eco-Friendly Resins – Water-based or low-VOC resins, available from some resin suppliers, minimize environmental harm during production.

Polymers and resins shape our world, but their future lies in making them kinder to the planet.

How Do Polymers and Resins Impact Manufacturing Costs?

Polymers and resins drive cost efficiencies, making them indispensable in modern production.

- Lower Material Costs – Polymers are cheaper than metals, reducing expenses for manufacturers producing packaging or automotive parts.

- Energy Savings – Recycling polymers, like PET, uses less energy than mining metals, cutting production costs significantly.

- Production Efficiency – Resins enable fast-curing adhesives or coatings, speeding up assembly lines and reducing labor expenses.

- Durability Benefits – Long-lasting polymers and resins reduce replacement costs for products like pipes or electronic casings.

- Local Supply – Pakistan’s manufacturers benefit from affordable polymers and resins, sourced from local chemical suppliers to keep costs low.

How to Choose a Polymer Supplier in Pakistan?

Selecting a reliable supplier ensures quality polymers and resins for manufacturing needs.

- Diverse Product Range – Look for suppliers offering thermoplastics, thermosets, elastomers, and bio-based options for various applications.

- Quality Consistency – Trusted suppliers provide tested materials with uniform properties, ensuring reliable performance in production.

- Local Expertise – Suppliers familiar with Pakistan’s textile, packaging, and construction sectors can recommend tailored materials.

- Timely Delivery – Choose suppliers with efficient logistics to ensure bulk orders arrive on schedule, avoiding production delays.

- Sustainable Options – Opt for suppliers offering eco-friendly polymers and resins, like recycled or bio-based materials, to meet green standards.

What’s the Future of Polymers and Resins in Manufacturing?

Polymers and resins are evolving to meet modern demands, balancing performance with sustainability.

- Green Innovations – Bio-based polymers and low-impact resins reduce reliance on fossil fuels, gaining traction in eco-conscious markets.

- Smart Materials – Self-healing resins and conductive polymers are emerging for advanced applications in medical devices and electronics.

- Recycling Advances – Chemical recycling breaks down polymers into reusable monomers, supporting a circular economy and reducing waste.

- Automation Integration – Polymers enable 3D printing and automated molding, streamlining manufacturing for precision and speed.

- Pakistan’s Growth – Local suppliers are adopting sustainable practices, positioning Pakistan as a hub for innovative polymer manufacturing.

The next wave of manufacturing will ride on polymers and resins that are smarter, greener, and tougher than ever.

FAQs About Polymers and Resins

What are polymers and resins?

Polymers are large molecules made of repeating monomers; resins are polymers used for coatings, adhesives, or composites in manufacturing.

Why are polymers and resins so widely used?

They’re affordable, lightweight, and customizable, making them ideal for packaging, textiles, automotive, and electronics industries.

Are polymers and resins safe for consumer products?

Most are safe when manufactured to standards, used in food containers, clothing, and medical devices, with rigorous testing.

How do polymers and resins impact the environment?

Non-biodegradable types contribute to waste, but recycling and bio-based options, like PLA, reduce environmental harm.

Which industries rely most on polymers and resins?

Textiles, packaging, construction, automotive, and electronics heavily use them for durability, cost, and versatility.

How can I find a reliable polymer supplier in Pakistan?

Seek suppliers in Karachi or Lahore with diverse, tested polymers, local expertise, and eco-friendly options for reliable supply.

What’s the difference between thermoplastics and thermoset resins?

Thermoplastics melt and reshape when heated; thermosets harden permanently, suited for coatings or adhesives.

Are there sustainable polymer options available?

Yes, bio-based polymers and recycled resins reduce environmental impact, offered by select suppliers in Pakistan.

Wrapping Up

Polymers and resins are transforming modern manufacturing, offering lightweight, durable, and cost-effective solutions for everything from plastic bottles to car coatings. Their adaptability fuels industries like textiles, packaging, and construction, while innovations like bio-based materials address environmental concerns. In Pakistan, where manufacturing drives economic growth, chemical supplier provide the materials to keep industries thriving. Whether you’re scaling up production or curious about the science behind your daily goods, polymers and resins are shaping a smarter future. Ready to power your next project? Connect with a trusted supplier and let these materials mold your vision into reality!